How the performance of cell and cell-derived products gets a boost from low-shear separation solutions

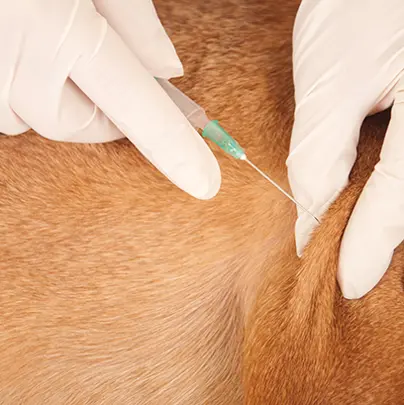

In the realm of cell and gene therapies, as well as biologics derived from cells, the preservation of cell viability is a fundamental concern. Developers must be able to perform separation quickly, efficiently, and most importantly without damaging the biological products they are processing. This article explores the significance of low-shear separation and delves into the principles of tubular bowl centrifugation, comparing it to alternative technologies.

The Significance of Low Shear Separation

During cell processing, the integrity of cells is paramount, especially when working with more sensitive cell lines used in advanced therapies. It is of utmost importance to address the effects of shear forces that emerge during the cell separation process. These shear forces can arise from factors such as flow paths, pressure changes, and peristaltic pumping, potentially leading to severe consequences such as cell death or undesirable metabolic cascades.

Importantly, cell health cannot be solely assessed through viability measurements. Viability measurements may not capture subtle damage or negative effects that can impact cell functionality and longer-term performance.

The loss of cell viability during separation has two primary effects:

1. Reduced Yield and Performance: When cells are the desired product, lower viability requires developers to produce more cells to serve a patient or population, leading to increased costs and potential challenges with availability. Additionally, changes in viability can lead to questions about the surviving cells' functionality post-separation.

2. Increased Impurities: When the supernatant is the desired product, the loss of cell viability introduces intracellular contaminants, such as host cell proteins, enzymes, DNA, and RNA, into the product stream. These contaminants can complicate downstream processing steps, including filtration and purification.

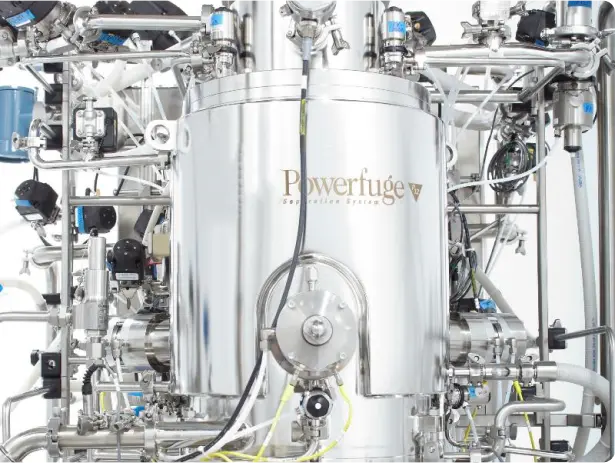

Tubular Bowl Centrifugation: A Solution for Low Shear Separation

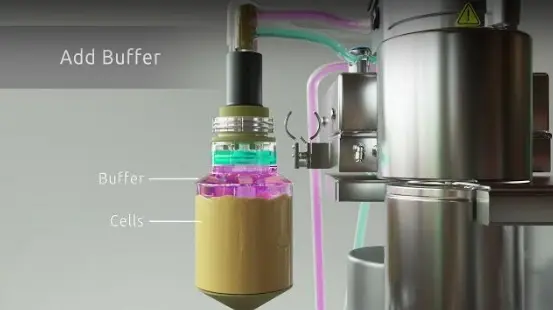

Tubular bowl centrifugation offers a distinct advantage in achieving low-shear separation. This advantage is attributed to the way cells are introduced into the centrifuge and the straightforward, low-surface-area geometries compared to alternative technologies.

In this process, cells are introduced into the center of the bowl, where they encounter the section with the lowest velocity first. As they travel toward the outer portions of the accelerator and bowl, they are gradually accelerated. Once captured at the outer wall of the centrifuge bowl, the cells remain undisturbed until the rotation is stopped for discharge.

Contrasting with Alternative Technologies

Alternative separation technologies face challenges in maintaining cell viability:

- Slow Processing Speeds: Centrifuge technologies, such as counterflow, have low working volumes that require multiple cycles to process a batch, or limited flow rates which contribute to longer processing times. The increased operating time outside of controlled conditions, such as a bioreactor or before cooling in preparation for cryogenic storage, can result in reduced viability or cell health. Additionally, the long processing times reduce manufacturing efficiency.

- Complex Flow Paths: Technologies, such as stacked disc, incorporate multiple components or intricate flow paths, potentially perturbing the normal flow and increasing shear forces that can impact cells and debris in the supernatant.

- G-Force Variation: In contrast to tubular bowl centrifugation, disc stack relies on higher g-forces for efficient separation, which poses challenges in maintaining cell health of sensitive cell lines used to manufacture advanced therapies. Despite efforts to address cell viability in alternative technologies, there may be limitations in maintaining cell health, as indicated by reduced functionality and growth in certain applications.

Conclusion

Achieving low shear separation is paramount for preserving cell viability. Tubular bowl centrifugation, with its inherent advantages in low-shear separation, presents a promising solution compared to alternative technologies. The choice of centrifugation technology should be made thoughtfully, taking into account the specific requirements – shear, processing speed, and separation efficiency - of the application and the delicate nature of the cells involved. This advancement in low shear separation is a significant milestone in bioprocessing, paving the way for more efficient and reliable processes.